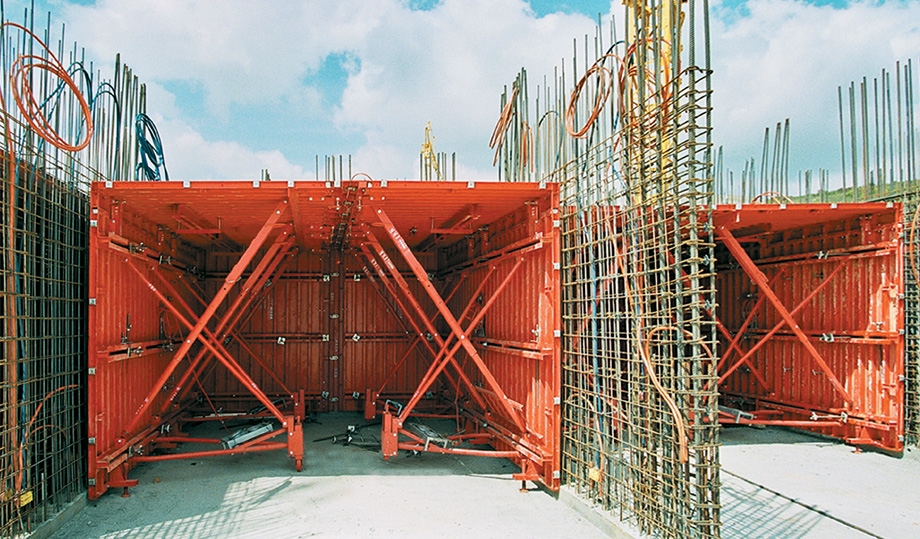

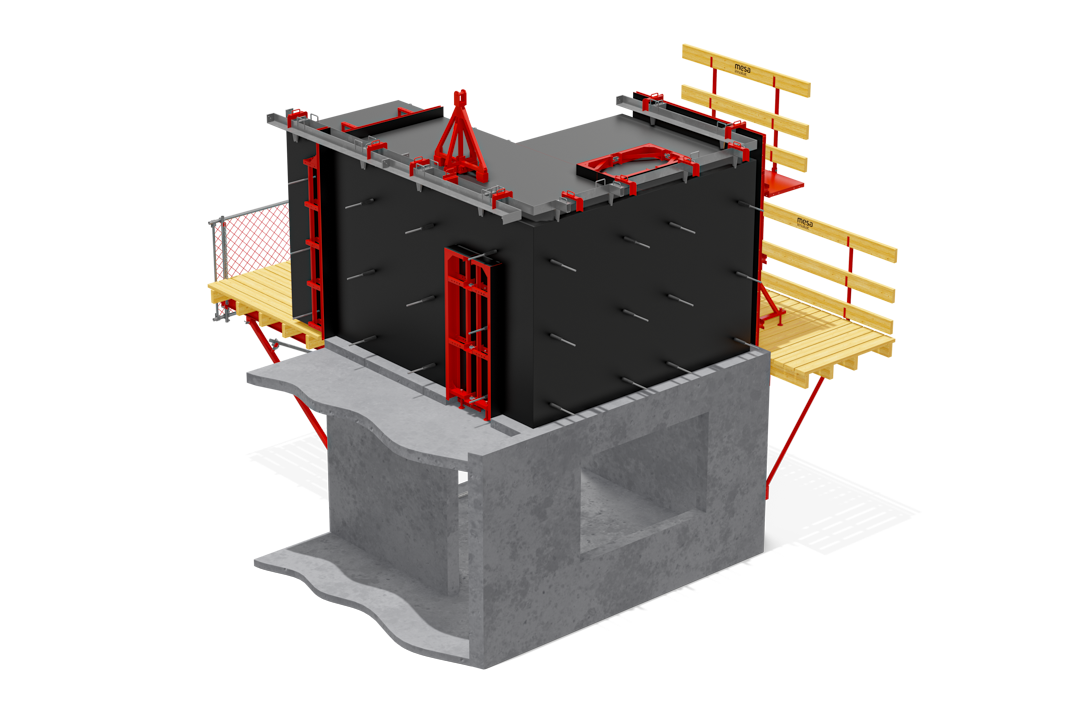

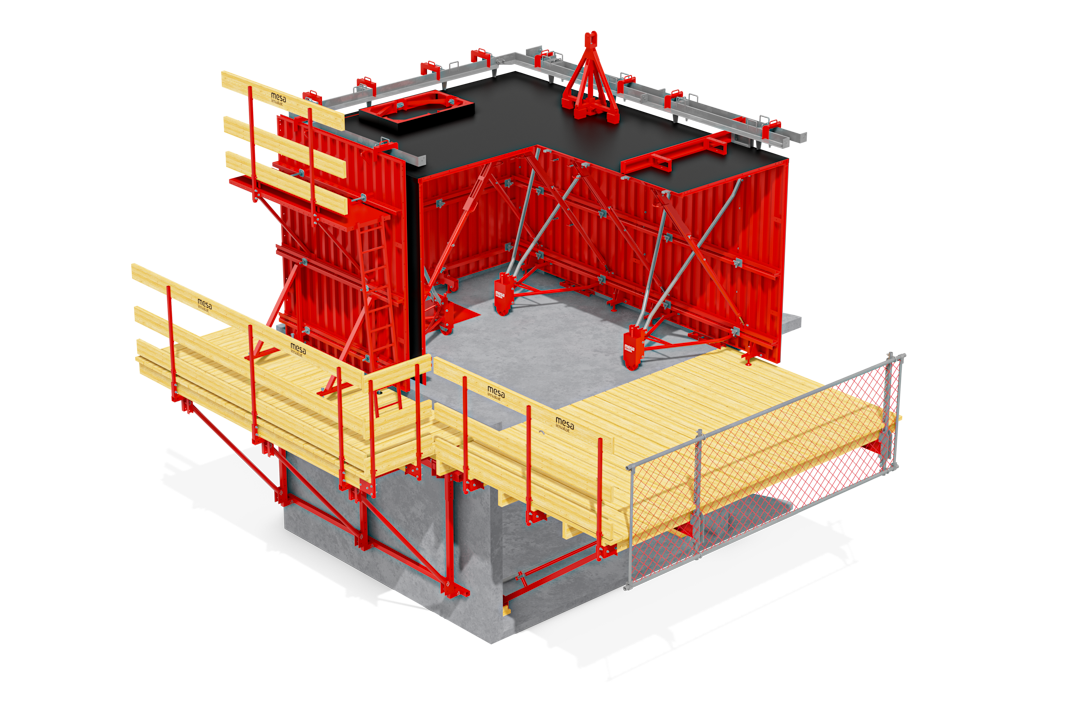

Tunnel Form is a system that allows casting of walls and slabs in one operation on a daily cycle. Construction durations are reduced significantly by this rapid system when compared to conventional methods. Tunnel Form System brings speed, quality and accuracy to concrete construction and provides big savings in finishing and M&E works. Hi-tech steel formwork surface provides high quality concrete finishes. The system creates efficient load-bearing structures which are known as the most earthquake resistant structures.

Main feature of tunnel form system is to transform building construction almost into an industrial production line by systemizing daily works into repetitive activities like a factory production which eventually provides highest efficiency on site with daily cycle

Advantages:

Durable System: High-tech all-steel system provides durability and strength. Service life of ERTF Tunnel Form system is good for 500 reuses as long as the system is used properly in accordance with instructions.

Surface Quality: Steel panel surface provides smooth concrete finish and reduce finishing works and repair need.

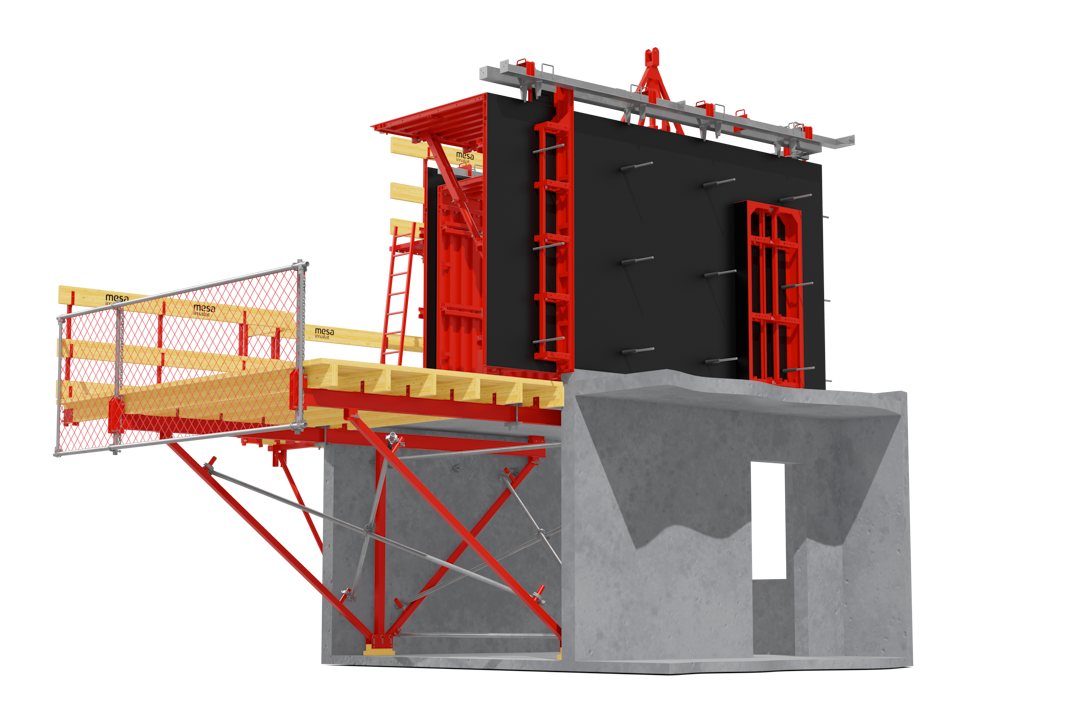

Work safety: Tunnel form system comes with highest jobsite safety due to full perimeter platform system.

Modularity of Panels : ERTF system is a new generation design which can be reused for several projects with minimum cost due to its modular nature. Standard size vertical, horizontal and back panels are used with extension filler panels to fit different spans and floor heights easily.

Practical Push- Pull Props :. Telescopic push-pull props make it very easy to adjust vertical and horizontal leveling.

Easy stripping with rollers : ERTF Half tunnels can easily be moved and stripped out by the help of rollers used instead of wheels.

Tunnel Extension Legs for non-typical floors: Tunnel Form System can be used at non-typical floors with higher floor levels by the help of telescopic extension legs mounted on vertical panels. Such floors can be cast in two steps easily by elevating the system.